Thermal Fluid Analysis

Sales brochure on WearCheck's thermal fluid analysis program....

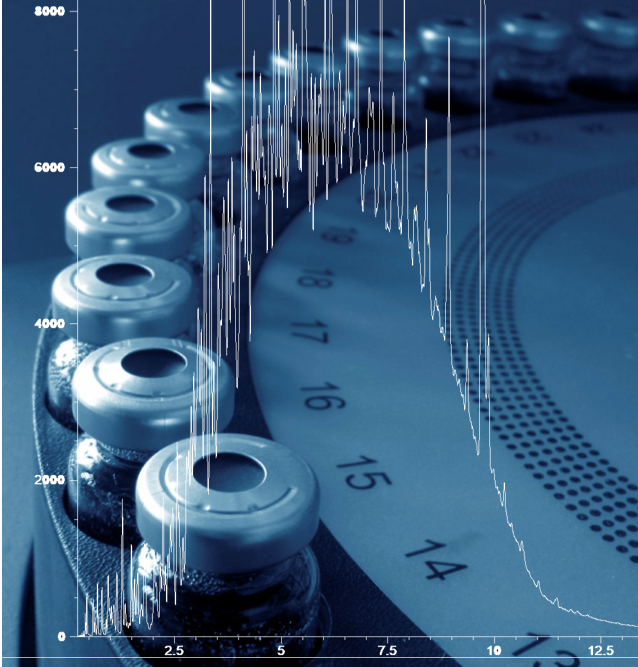

In many industries heat transfer systems are critical to the operation of the business. Maximizing heat transfer efficiency is key to reducing operating costs, and a WearCheck thermal fluid analysis program is essential to achieving this efficiency. WearCheck's thermal fluid analysis package provides a comprehensive test package to monitor all aspects of the fluid condition, to detect fluid contamination and degradation, and assess the potential for any fluid bumping or flammability hazards.

WearCheck's thermal fluid testing package cover all areas of analysis. An assessment of fluid quality and contamination assists you to ensure efficient heat transfer and minimize flammability risks in your operation. Thermal fluids are subject to degradation as well as contamination from condensation and cooler leaks. Fluid degradation decreases the efficiency of heat transfer and the presence of water in thermal fluids can lead to bumping. WearCheck's Thermal Fluid Analysis program is designed to monitor for degradation and contamination including water, and insolubles that lead to fluid bumping, corrosion, and the deterioration of thermal fluids that lead to decreased heat transfer efficiency.

WearCheck provides you with clear and concise directions, forms and sample containers needed to submit thermal fluid samples to the WearCheck laboratory. After you have taken fluid samples from the heat transfer system simply fill out the information sheets and submit these forms with your samples to the laboratory.

WearCheck's thermal fluid analysis is effectively used today for a broad range of thermal and heat transfer fluids operating in a wide variety of industries including asphalt production, food industry, coatings industry and general manufacturing.

| Test | Test Method | Description | HTTF- | HTTFL |

|---|---|---|---|---|

|

ICP Analysis ASTM D5185 |

Determines the parts per million (ppm) of all wear metals (Fe, Cr, Ni, Pb, Cu…), contaminants (Si, Na, K….), and additives (Ca, P, Zn, Mg, Mo…). | ||

|

Water Content ASTM D6304 |

Determines level of moisture or water contamination in the oil. | ||

|

Acid Number ASTM D664/D974/D8045 |

Determines overall acidity (AN) of the oil which is an indication of degradation. Single best test to determine change-out interval. AN for non-engine oil samples. | ||

|

Viscosity ASTM D445/D7279 |

Determine the viscosity of the oil at 40°C (non-engine), or 100°C (engine) to determine if oil is still within specification. High viscosity can indicate oxidation, low viscosity can indicate contamination, improper make-up oil. | ||

|

Flash Point ASTM D93/D7215 |

Determination of the Pensky-Martens closed cup flash point by closed-cup testing apparatus or calculated from SimDis. Low flash points can present a flammability hazard. | ||

|

Visual Screen WC Method |

A picture of both the oil color/clarity and the bottom of the sample bottle are taken, and any level of contamination, visual oil problems or visible wear debris of the oil is recorded. | ||

|

Simulated Distillation ASTM 2887 |

Determines quantitatively the boiling range characteristics of the fluid. Identifies issues with thermal cracking and fluid degradation. | ||

|

Pentane Insolubles ASTM D4055 |

Directly measure the amount of pentane insolubles present in the oil. Provides a determination of the amount of sludge forming materials present in the oil (varnish and shellac pre-cursors). |

Check with your local WearCheck laboratory regarding which specific ASTM test methods are utilized.

WearCheck Thermal fluid Analysis includes everything to set-up a complete Thermal fluid analysis program. When you purchase a WearCheck Thermal fluid analysis program you will receive our simplified sample kits (QR-coded bottles & sample forms with mailing packs). All WearCheck Thermal fluid analysis programs include laboratory testing, sample diagnosis and recommendations, sample report, and access to our patented WebCheck™ system, and companion mobile application to manage your Thermal fluid analysis program.

WearCheck offers additional programs for Fleet Vehicles, Off-Road Construction, Mobile Equipment, Fixed Plant Machinery, Marine Equipment, Wind Turbine Industry, Aviation/Avionics Systems, Advanced Oil Monitoring, Coolant Analysis, Diesel/Marine/Jet Fuel Analysis, Transformer Fluid Analysis, Grease Analysis, Wear Particle Analysis, Honeywell TPE-331/TFE-731 SOAP Service.