Talking Transformer Testing

Condition monitoring is the frequent collecting, measuring, recording, and analysis of the relevant...

Your primary concern as a business is to be profitable. All too often, these days, this requires an increase in profit through a reduction in costs. A well run condition monitoring program will achieve a substantial reduction in costs. WearCheck’s transformer fluid analysis packages offer you condition monitoring for your insulated electrical equipment. WearCheck offers three levels of analysis, from basic to advanced test kits, to meet your analysis requirements.

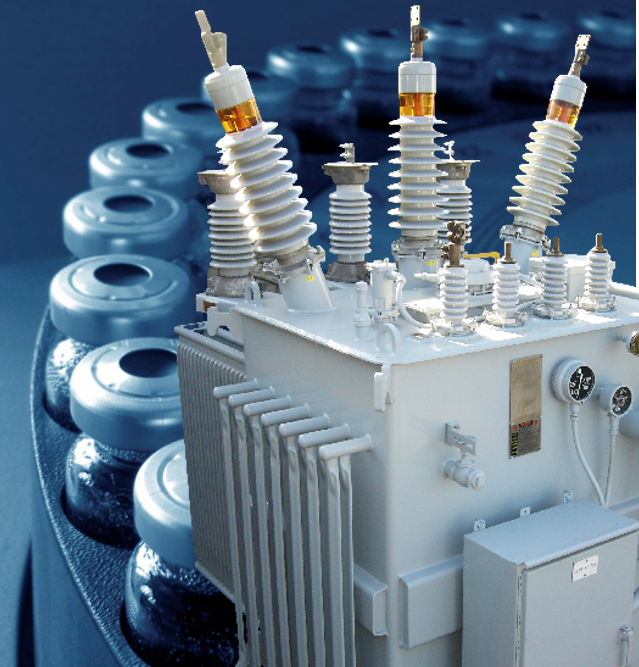

Transformers and oil filled insulating systems are usually large investments and provide the most important aspect to the majority of all industries. Power. Transformers account for the biggest investment in an electrical installation, and the indirect costs of an unscheduled shutdown are significant. To avoid unnecessary costs utilize transformer fluid analysis to ensure that transformers are operating reliably. Industry experience indicates that about 20% of transformers have latent defects that could result in an unscheduled shutdown.

Transformers can be affected by a wide range of internal and external conditions which, over time, may lead to rapid fluid ageing which can affect the internal insulation and windings and as a result lead to a reduction in the equipment reliability. Costly downtime can be averted by implementing a cost effective transformer fluid analysis program. Fluid analysis provides a diagnostic state of the transformer and insulation system through a series of tests of the dielectric oil. Once the appropriate testing has been carried out, a report of the results, including an analysis of the fluid and system condition is provided.

A WearCheck Technical Representative will recommend the proper test kits for your equipment. WearCheck provides you with clear and concise directions, forms and sample bottles and syringes required to submit samples to the WearCheck laboratory. After you have taken the appropriate samples of fluid from the transformer, simply fill out an information sheet and submit the form along with your sample to the laboratory.

WearCheck’s transformer fluid analysis is effectively used today for a broad range of transformer fluids, dielectric oils and insulating fluids.

| Test | Test Method | Description | TRF1 | TRF2 | TRF3 |

|---|---|---|---|---|---|

|

Dielectric BDV ASTM D1816 |

The dielectric breakdown is the voltage at which the insulator no longer prevents an electrical discharge across two electrical contacts submerged into the fluid. | |||

|

Interfacial Tension ASTM D971 |

A measure of the fluids surface tension as compared to water. Decreases in interfacial tension are an indication of fluid degradation. | |||

|

Specific Gravity ASTM D1298 |

Different insulating fluids have varying specific gravities. A sudden change in the specific gravity is an indication of contamination by a different insulating fluid. | |||

|

Acid Number ASTM D664/D974/D8045 |

Determines overall acidity (AN) of the oil which is an indication of degradation. Single best test to determine change-out interval. AN for non-engine oil samples. | |||

|

Water Content ASTM D6304 |

Determines level of moisture or water contamination in the oil. | |||

|

ASTM Color ASTM D1500 |

Determines the ASTM color of the oil product. Indication of the degree of oil refinement and useful in determining when the oil is grossly contaminated, oxidized or thermally degraded. | |||

|

Dissolved Gas Analysis ASTM D3612 |

Dissolved Gas Analysis is a must have tool to ensure your equipment remains in peak condition. By looking at concentrations of specific combustible gases then applying various diagnostic tools to identify fault conditions within the system. | |||

|

Furans HPLC |

Furan analysis monitors derivatives in the fluid that identify possible deterioration or ageing of the solid insulation. |

Check with your local WearCheck laboratory regarding which specific ASTM test methods are utilized.

Condition monitoring is the frequent collecting, measuring, recording, and analysis of the relevant...

Sales brochure on WearCheck's transformer/insulating fluid analysis programs....

WearCheck Transformer Analysis includes everything to set-up a complete Transformer analysis program. When you purchase a WearCheck Transformer analysis program you will receive our simplified sample kits (QR-coded bottles & sample forms with mailing packs). All WearCheck Transformer analysis programs include laboratory testing, sample diagnosis and recommendations, sample report, and access to our patented WebCheck™ system, and companion mobile application to manage your Transformer analysis program.

WearCheck offers additional programs for Fleet Vehicles, Off-Road Construction, Mobile Equipment, Fixed Plant Machinery, Marine Equipment, Wind Turbine Industry, Aviation/Avionics Systems, Advanced Oil Monitoring, Coolant Analysis, Diesel/Marine/Jet Fuel Analysis, Thermal/Heat Transfer Fluid Analysis, Grease Analysis, Wear Particle Analysis, Honeywell TPE-331/TFE-731 SOAP Service.