Fuel Analysis

Sales brochure on WearCheck's fuel testing programs....

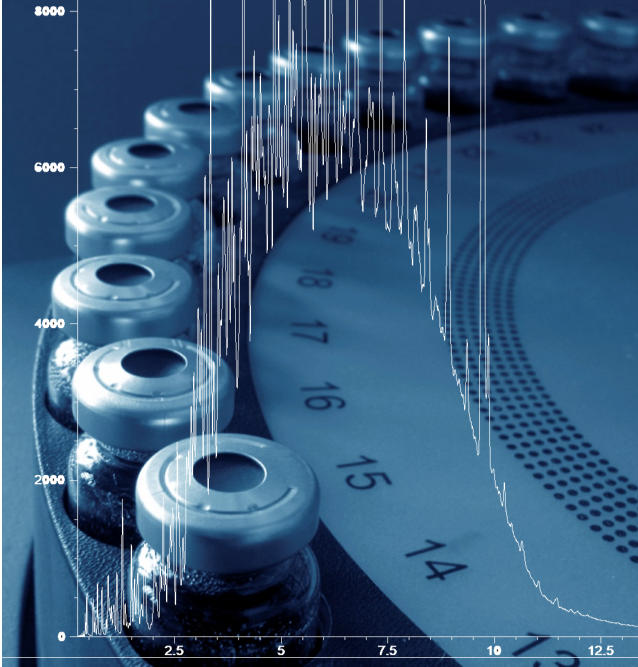

In many industries fuel is the largest single on-going operating cost. Maximizing fuel usage efficiency is key to reducing operating costs, and a WearCheck fuel analysis program is essential to achieving this efficiency. WearCheck's fuel analysis packages offer you a range of testing to ensure fuel quality and adherence to federal specifications, detect fuel contamination and degradation, and where a flammability hazard exists requiring fire risk assessment, that your fuel meets regulatory and insurance requirements.

WearCheck's fuel test packages cover all areas of analysis. An assessment of fuel quality and volatility assists to prevent power loss, carbon deposits and smoke formation and ensure optimum fuel performance for your machinery. Fuel stored in bulk tanks or standby equipment/generators are subject to the formation of degradation by-products and contamination. WearCheck's Fuel Analysis program is designed to monitor for degradation and contamination including water, sediment, and microbial growth that lead to corrosion, filter-plugging, and the deterioration of fuel performance and fuel system fouling.

WearCheck provides you with clear and concise directions, forms and sample bottles needed to submit fuel samples to the WearCheck laboratory. After you have taken fuel samples, from storage, delivery of machinery, simply fill out the information sheets and submit these forms with your samples to the laboratory.

WearCheck's fuel analysis is effectively used today for a broad range of fuels operating in a wide variety of industries including diesel fuel, aviation and marine fuels, and gas turbine fuel oils.

| Test | Test Method | Description | DF1 | DF2 | DF3 | DF5 |

|---|---|---|---|---|---|---|

|

ICP Analysis ASTM D5185 |

Determines the parts per million (ppm) of all wear metals (Fe, Cr, Ni, Pb, Cu…), contaminants (Si, Na, K….), and additives (Ca, P, Zn, Mg, Mo…). | ||||

|

Cetane Index ASTM D4737 |

Standard test method for calculated cetane index by four variable equation. Cetane index provides a measure of fuel ignition quality. | ||||

|

Sulfur Content ASTM D5185/5453 |

Measurement of the sulfur content in the fuel by dispersive X-ray Spectrometry or Inductively Couple Plasma (ICP) Spectrometry to verify S15, S500 or S5000 specification. | ||||

|

Viscosity ASTM D445/D7279 |

Determine the viscosity of the oil at 40°C (non-engine), or 100°C (engine) to determine if oil is still within specification. High viscosity can indicate oxidation, low viscosity can indicate contamination, improper make-up oil. | ||||

|

Particle Count ASTM D7647 |

Determine cleanliness levels of oil to ISO4406:1999. High particle count levels can indicate gross contaminant ingress, wear, filter by-pass or all of these issues. | ||||

|

Distillation/SimDis ASTM D86/D2887 |

Determines quantitatively the boiling range characteristics of the fuel. Assists in the determination of the cetane index and closed-cup flash point and can identify impurities in the fuel. | ||||

|

API Gravity/Density ASTM D7777 |

Standard test method for density, relative density and/or API gravity of liquid petroleum by portable digital density meter. | ||||

|

Flash Point ASTM D93/D7215 |

Determination of the Pensky-Martens closed cup flash point by closed-cup testing apparatus or calculated from SimDis. Low flash points can present a flammability hazard. | ||||

|

Could/Pour Point ASTM D5771/D5950 |

Determination of the cloud point and/or pour point of the fuel to determine the low temperature operating range of the fuel. | ||||

|

Water & Sediment ASTM D1796/D2709 |

Determination of the amount of free water and sediment present in the fuel by centrifugal method. Excessive water causes corrosion and sediment can lead to fuel system fouling. | ||||

|

Microbial Content ASTM D6469 |

Multi-day test wherein agar is inoculated with the fuel sample and the amount of bacteria, fungi and/or mold colonies developed are counted and reported. |

Check with your local WearCheck laboratory regarding which specific ASTM test methods are utilized.

- Test included with test package.

- Water & Sediment and Microbial Content testing is only performed when other tests warrant or by special request

WearCheck Fuel Analysis includes everything to set-up a complete Fuel analysis program. When you purchase a WearCheck Fuel analysis program you will receive our simplified sample kits (QR-coded bottles & sample forms with mailing packs). All WearCheck Fuel analysis programs include laboratory testing, sample diagnosis and recommendations, sample report, and access to our patented WebCheck™ system, and companion mobile application to manage your Fuel analysis program.

WearCheck offers additional programs for Fleet Vehicles, Off-Road Construction, Mobile Equipment, Fixed Plant Machinery, Marine Equipment, Wind Turbine Industry, Aviation/Avionics Systems, Advanced Oil Monitoring, Coolant Analysis, Thermal/Heat Transfer Fluid Analysis, Transformer Fluid Analysis, Grease Analysis, Wear Particle Analysis, Honeywell TPE-331/TFE-731 SOAP Service.